Field of applications

Customized & European CE safety standards

» Needle thread barcode scanner

» 2 loading stations with sliding tables for optimized cycle time and maximal machine

utilization

» Housing - protection for operators against automatic movement of the machine

» Emergency stop button located in every loading station

» Status light of the sewing machine on every corner

» 5214-6060-LH-B 600x600mm with double table feeding station

» 5214-12060-LH-B 1200x600mm

» 5214-12060-LH-B 1200x600mm with double table feeding station

» 5214-12090-LH-B 1200x900mm

» 5214-12090-LH-B 1200x900mm with double table feeding station

Versions

Features & Technical data

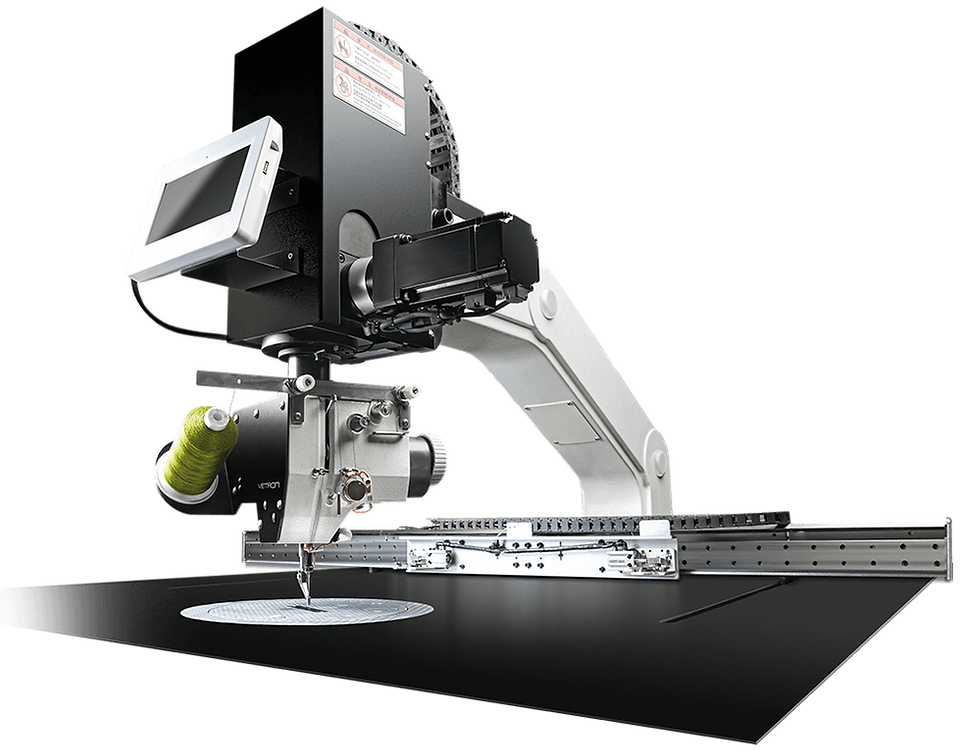

5214

» 360° turning head

» Programmable needle thread tension (for each stitch)

» Needle thread monitor

» Programmable needle thread clamp for a clean seam start

» Vibrating presser foot, programmable stroke from 0-9 mm

» Big foot to hold down clamp, lowest niveau adjustable

» Up and down movable head for extended clearance of 55 mm under the feet

» Big vertical hook, bobbin diameter 32 mm

» Bobbin thread sensor

» External electronic bobbin winder

» Intermitted clamp feed (clamp stands still when needle is penetrating material)

» Stitch length programmable from 0,05-12,7 mm

» Rotating angle programmable in 0,05° steps

» RFID reader integrated in clamp drive mechanism to identify clamp and recall of

corresponding sewing program

» Max. sewing speed 2.500 stitches / minute (depending on thread, material and

machine settings)

» Max. number of stitches 20.000

» Touch screen control and program panel with USB port for up- and download of

sewing files

» dxf files are easy to convert and upload to sewing machine

» Siemens CPU S7-1500

» European CE safety standards. All moving parts are protected by a safety light fence

» 230 Volt, single phase. 6 bar compressed air, ~ 1,7l/min

* Depending on process

** Depending on version

Human-Machine communication

To supervise the production process and avoid potential mistakes, process-specific poka-yoke functions are available. With the assistance of sensors, RFID- and barcode scanners a diverse list of criteria can be checked before the clearance to start is given.

For templates with one part, the correct sewing program can be loaded via an RFID tag attached to the template. If a template is designed to fit multiple parts, the sewing program is chosen for the number of inserted parts.

» Premium material and built quality

» Weight optimized construction

» Seam blades and eccentrics as positional aids

» Intuitive Verschlusssysteme

» QR-code assisted monitoring of templates

Always fit to the application

Sewing template

As a supplement to the 5214 VETRON offers the production of sewing templates.

In addition, the manufacture of special accessories is possible according to individual customer requirements.

Communication between VETRON 5214 and the tracebility system of the customer

Customizable poka yoke equipment for example

» Identification of parts presence inside the jig

» Recognition of jigs are closed

» Matching between parts and colour of the thread

QR-code assisted monitoring of templates

Sewing programs

PROGRAM #VETRON 000256

PROGRAM #VETRON 300452

PROGRAM #VETRON 777086

PROGRAM #VETRON 822234

PROGRAM #VETRON 008253

QR-code assisted monitoring of the use of a workpiece

Workpiece in the template

2 table use

No workpiece in the template 1 table use

Matching between parts and colour of the thread

Thread color - Black

Thread color - Red

Thread color - White

Part color #B345T1

Part color #F0F0ER

Part color #B1B2A4

Part color #00E4T3

All informations in one place!

Direct download

Here you can find all information about the machines in one place!

Are you looking for the right operating or programming instructions?

With the direct download you have access to all information. Would you like to see the machine in action? Visit our Youtube Channel. Is the corresponding machine not yet online, so contact us. We will produce a product film to the machine as soon as possible.