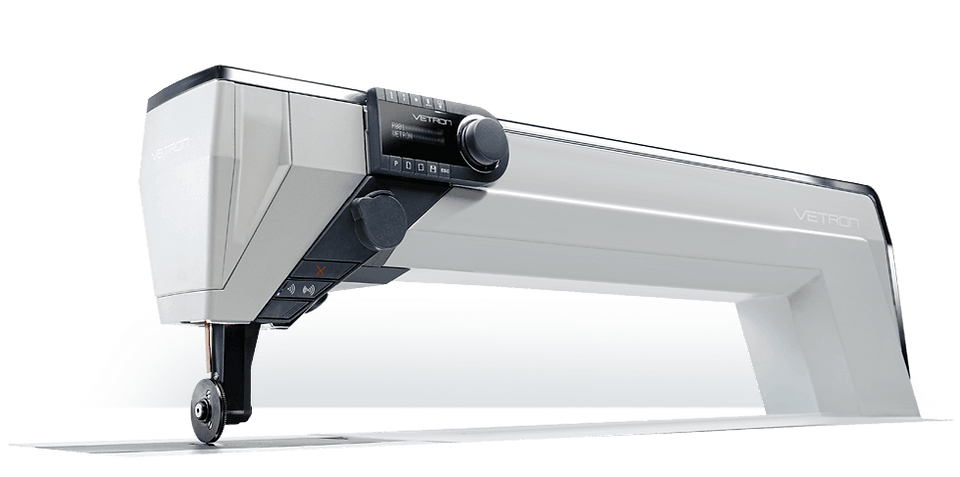

VETRON 5164

Electronic flat bed ultrasonic welding machine with sonotrode and anvil wheel 25 / 45 mm diameter

Ultrasonic welding machine with unique features

The ultrasonic approach has developed as forward looking method for the connection of thermoplastic, innovative and technical materials.

For the connection of technical (weldable) materials, such as protective clothing made of TYVEK, car covers for transport, medical mattresses and pads, clean room clothing, filter, sports gear, etc., an innovative ultrasonic welding machine is indispensable, in order to guarantee the best possible resistance of the welding seam.

The VETRON 5064 and 5164 (longarm version) with its worldwide unique selling features emerges as the perfect partner for ultrasonic welding techniques.

The calibrated height sensor measures the distance between anvil- and sonotrode wheel over the entire perimeter. This ensures an exact concentricity and leads to a perfect welding seam with steady quality. After finishing the distance- and concentricity-calibration, the accuracy of the concentricity is shown on the display. VETRON offers two sonotrodes made of hardened steel and titanium.

The detachable display/panel guarantees a high process security, since no program or parameter change can be made when removed. Programs can be changed or uploaded to the machine via an USB Slot.

Field of applications

High tech as standard

Through the consistent use of state of the art electronic control it became possible to make all machine settings programmable into memory and thus recallable.

This allows the process parameters to be free from operators influence and identical every time the program is recalled.

Programmable Setup

All machine settings are programmable and storable.

Fast and precise setup of the machine by recall of a stored machine program.

Easy to understand and intuitive programming concept.

Program chain function to combine different production steps directly on one machine.

User identification by USB-dongle to avoid access on machine settings - on demand.

Process Reliability

User identification via USB dongle (activated via parameters).

Operator has no access to basic parameters.

Different access levels for Operator / Line Supervisor / Technican / Technical Supervisor (Administrator).

Features & Technical data

5164

» Ultrasonic frequency 35 kHz

» Concentricity calibration

» Programmability of all welding parameters and thus reproducibility

» Equipped with differential feed; separate drive for sonotrode and anvil wheel; that means

smooth, non-distorted seams or the possibility of adding a some fullness

» Up to 199 programs can be created

» Welding speed adjustable from 0,5 mtr./min. up to 40,0 mtr./min. in 0,1 mtr./min. steps

» The anvil wheel size of 45 mm diameter allows for better visibility and better handling,

especially in curves. Alternativ 25 mm diameter is also available for extreme small curves

and edges

» Electronic hand wheel to turn the anvil and sonotrode, to proceed forward-backward

» Electronic button in the handling sector for short seam sections with opposite direction of

welding (rotation)

» Button in the action area for 2- power stage

» Security key and button wheel change button in the handling sector

» Easy selection of different languages in panel

» Electronic rear Puller (optional)

* Depending on process

Control Panel P107

Simple operation - easy to remove

The control panel concept P107 is one of the new generations of control panels. It guarantees easy operation with simple navigation.

In the production is this operating concept ideally suited for setting the sewing parameters and sewing programs / sequences. The control panel is simply removed after setting - the operator can no longer intervene in the sewing parameters.

All informations in one place!

Direct download

Here you can find all information about the machines in one place!

Are you looking for the right operating or programming instructions?

With the direct download you have access to all information. Would you like to see the machine in action? Visit our Youtube Channel. Is the corresponding machine not yet online, so contact us. We will produce a product film to the machine as soon as possible.