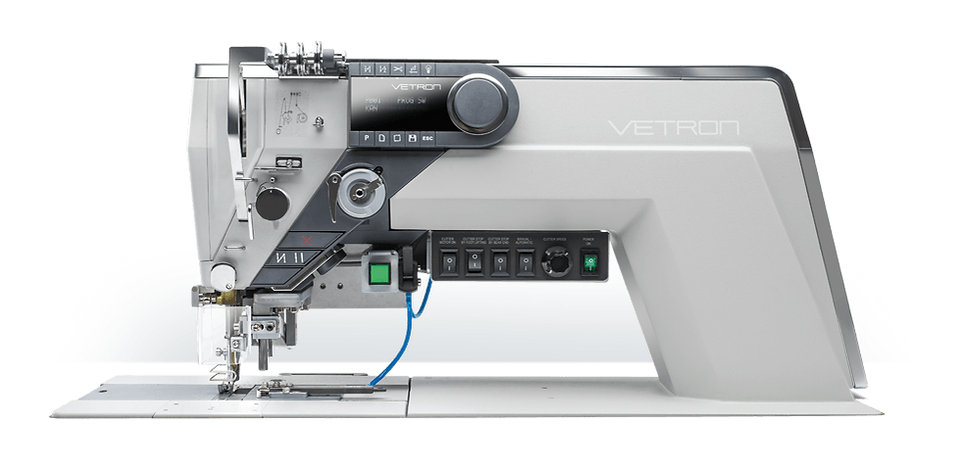

VETRON 5040 with Edge trimmer

Direct-drive 1-needle lockstitch sewing machine with triple transport and edge trimmer

Innovative and user-friendly edge trimmer for the automotive and upholstery industry

The new edge trimmer of the VETRON 5040 is characterized by excellent features in operation and processing for butt seams in the automotive and upholstery industry.

The control element with manual and automatic functions is located low-noise in easy reach of operator. The low-noise and low-vibration run of the edge cutter make the VETRON 5040 the best working partner in production.

The knife motor control offers different usage options between an manual and automatic work mode. Both, in manual and in automatic mode, the speed is controlled by a potentiometer. Functions as „cutter stop by foot lifting“ or „cutter stop at seam end“ can be combined using by toggle switch. In automatic mode, the edge trimmer only runs while sewing.

Field of applications

Features - Edge Trimmer

» Motor-driven edge cutter with a trimming margin of

1,6 mm (other cutting margins available on request)

» Control elements of the edge trimmer in easy reach of

operator

» Low-noise, low-vibration running, even at top speed

» Edge trimmer drive is independent of the sewing

machine speed

» Manuell / automatic mode

» Switchable function „cutter stop by foot lifting“ and

„cutter stop at seam end“

Features & Technical data

5040 Edge trimmer

» Motor-driven edge cutter with a trimming margin of 1,6 mm

(other cutting margins available on request)

» Control elements of the edge trimmer in easy reach of operator

» Low-noise, low-vibration running, even at top speed

» Edge trimmer drive is independent of the sewing machine speed

» Manuell / automatic mode

» Switchable function „cutter stop by foot lifting“ and „cutter stop at seam end“

» Stitch type 301

» Max. stitch length 5 mm

» Max. top-feed-stroke 9 mm

» Max. clearance under the sewing feet 20 mm

» Automatic top-feed-stroke adjustment

» Controlled needle thread tension

» Automatic adjustment of presser foot pressure

» Electric driven bobbin winder

» Electronic hand wheel

» Electronic back-tack lever

» Automatic thread cutter for threads up to 20/3; thread ends ~13 mm

» Integrated LED sewing light

* Depending on process

** Depending on version

High tech as standard

Through the consistent use of state of the art electronic control it became possible to make all machine settings programmable into memory and thus recallable.

This allows the process parameters to be free from operators influence and identical every time the program is recalled. The innovative dynamic machine parameter, based on the actual speed and the permanent measurement of the material thickness, open new possibilities of production quality, process security and the reduction of cycle times.

Control Panel P107

Simple operation - easy to remove

The control panel concept P107 is one of the new generations of control panels. It guarantees easy operation with simple navigation.

In the automotive production is this operating concept ideally suited for setting the sewing parameters and sewing programs / sequences. The control panel is simply removed after setting - the operator can no longer intervene in the sewing parameters.

More ease of use is impossible

Every operating element in the direct handle area

Electronic bobbin winder

Forward/backward selection key

Electronic hand wheel

Programmable button

Safety button

Forward/backward slider

Always fit to the application

Gauge part sets and accessories

As a supplement to the sewing machine series, VETRON also offers standard sewing accessories & tools.

In addition, the manufacture of special accessories is possible according to individual customer requirements.

All informations in one place!

Direct download

Here you can find all information about the machines in one place!

Are you looking for the right operating or programming instructions?

With the direct download you have access to all information. Would you like to see the machine in action? Visit our Youtube Channel. Is the corresponding machine not yet online, so contact us. We will produce a product film to the machine as soon as possible.