With a total of 1,818 exhibitors from 59 countries and, in all, some 47,000 trade visitors from 116 countries, the two biggest editions of Techtextil and Texprocess ever to be held, ended today in Frankfurt. Accordingly, for four days, the Frankfurt Fair and Exhibition Centre once again became the leading international platform for users of technical textiles from the widest variety of sectors, as well as for manufacturers of apparel, fashionwear, upholstered furniture and leather products.

VETRON|TYPICAL presented itself once again with great success at the TEXPROCESS. Newest sewing and welding solutions, an operator friendly workplace design, the v_sion product-management-system as all-in-one industry 4.0 solution, as well as first-time 3D-Sewing and Welding-Systems did let the visitors venture in world full of innovation and German engineering art on an almost 800 sqm area.

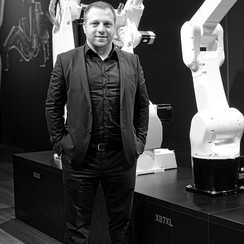

The newly developed VETRON VIPER 3D-Robotic-System did not only impress the visitors, but also won the popular TEXPROCESS INNOVATION AWARD. The Viper won the professionally qualified judges over with its ultra-light sewing machine, working with a weight of approx 7 kg and in cooperation with a 6-axis-robot as ultra-flexible and compact robotic-cell for various 3D applications. Thus, beside the award-winning sewing-system, a hotair-welding-system for dashboards was shown as well. It was the fifth award in a row, manifesting VETRON | TYPICALS position as the industrys leader of innovation.

In addition to the robot-systems, VETRON | TYPICAL presented the new robotic range as well as a unique material gripper. The VETRON VARIOGRIP can differ between flexible materials such as leather or fabric, and switches automatically between a vacuum- or needle-system to grab the material. The hub-arms of the VARIOGRIP identify different forms, which makes it a powerful addition for the transport between single processes within a production.

The market launch of the VETRON 5656 AutoSeam was long awaited. Awarded with the TEXPROCESS INNOVATION AWARD in 2015, the automatic sewing machine was developed to the point of market maturity in the years since. For the first time, non-congruent contours can be merged automatically.

The market launch of the AutoSeam is another big step forward for VETRON | TYPICAL as a pioneer in the man less sewing segment.

The Automation segment was complemented by two turning-head-systems with automatic shuttle tables for an overlapping operation. The VETRON 5412 turning-head-system also led to large visitor interest a part of the „SMART TEXTILES MICRO FACTORY“ of the Institut für Textiltechnik of RWTH Aachen University, short ITA. The ITA in cooperation with multiple partners showed a way to produce a smart textile from a design to an actual finished product for the first time.

TEXPROCESS 2019 will go down as another great success of VETRON | TYPICAL. Thanks to the steady extension of the product portfolio and the promising start of the new robotic segment, the company presented itself once again as a strong and reliable partner for the future.

Impressions from the TEXPROCESS 2019